How to Recreate Textured Wall Panels Using Jesmonite

- Jesmonite

- Sep 26, 2025

- 5 min read

In the vibrant world of interior wall design, where walls evolve from mere boundaries into captivating canvases, textured panels are stealing the spotlight. Imagine the sleek flutes of a ribbed surface catching the light in a boutique hotel lobby, or the subtle grit of microcement adding earthy depth to a cozy home retreat. Or, if you are looking for incredible external wall panels with a unique touch, bespoke design and personal feel… Jesmonite, our versatile raw material, shines here by empowering manufacturers to craft these trends into reality… delivering panels that are not just visually stunning but built to endure.

By showcasing breathtaking end products from our customers' projects, like those featured on jesmoniteprojects.com and our LinkedIn, we illustrate how Jesmonite transforms raw potential into polished perfection. Let's dive into recreating these textured wonders, step by colourful step.

Textured Wall Panel Trends in Homes, Hotels and External Places

As we step into 2026, interior trends are all about tactile indulgence, walls that beg to be touched, blending warmth with sophistication. Homes are embracing earthy palettes of greens, blues, and natural tones, ditching stark minimalism for textured layers that add depth and character. Think fluted panels evoking gentle waves, ribbed designs for a rhythmic flow, or microcement finishes that mimic raw, organic stone, perfect for creating serene bedrooms or inviting living spaces.

In hotels, the push is toward luxurious, multi-sensory experiences. Layered textures like embossed wallpapers, 3D panels, and faux stone effects dominate hospitality spaces, fostering high-end tactility in lobbies and suites. Eco-friendly materials are key, with sustainable wood slats, recycled composites, and natural stone replicas leading the charge for greener, more inviting environments. These trends aren't just aesthetic; they're functional, enhancing acoustics and insulation while turning walls into statement art. Manufacturers tapping into this can produce panels that hotels crave for their durability and custom flair, as seen in Jesmonite-powered projects like the immersive rockwork at London Zoo's Land of the Lions enclosure.

How Jesmonite Makes It Easier and More Durable

Jesmonite stands out as a game-changer for manufacturers crafting textured wall panels, a water-based, acrylic-modified gypsum composite that's lightweight yet robust, with ultra-low shrinkage to prevent cracks and distortions. Unlike traditional concrete or GRC, Jesmonite's two-pack system (liquid and powder) mixes effortlessly, flowing into intricate moulds to capture every flute, rib, or microcement nuance with precision. Its rapid setting times slash production cycles, while lower curing temperatures cut energy costs, making it a sustainable powerhouse for large-scale output.

Durability? Jesmonite delivers high impact strength, extreme weather resistance, and non-combustible properties, ensuring panels thrive in humid hotel bathrooms or sun-drenched home atriums. For manufacturers, this means creating end products like bespoke feature walls or architectural claddings that outlast competitors, think the silver-grey granite panels in our tutorials or the custom colour-matched facades shared on LinkedIn. It's not just easier; it's smarter, allowing vibrant finishes that mimic stone, metal, or terrazzo without the heft or hassle.

Making or Sourcing Panel Moulds

The magic starts with the mould, your blueprint for texture. For fluted or ribbed designs, craft custom silicone rubber moulds using a master model sculpted from foam or clay; Jesmonite's exceptional flow captures fine details like subtle veining or gritty microcement surfaces. Manufacturers can scale this by rotocasting or spraying Jesmonite AC730 into large moulds for lightweight panels.

Sourcing ready-made moulds? Look to suppliers offering flexible silicone options for standard textures, fluted waves, ribbed lines, or microcement patterns. Reinforce with glass fibres for added strength in bigger panels, ensuring demoulding is smooth and reusable. This approach lets manufacturers prototype quickly, turning ideas into tangible end products like the metal-effect wall tiles in our Flex Metal projects. Pro tip: Always apply a release agent for flawless extraction, keeping your production line humming.

So, you can:

Buy pre-made moulds from specialist suppliers.

Create custom moulds with CNC-cut patterns, timber masters, or 3D prints.

Experiment with texture mats for organic stone or plaster-like surfaces.

Jesmonite captures fine details exceptionally well, so even subtle grain patterns or marbled veining transfer crisply to the cast surface.

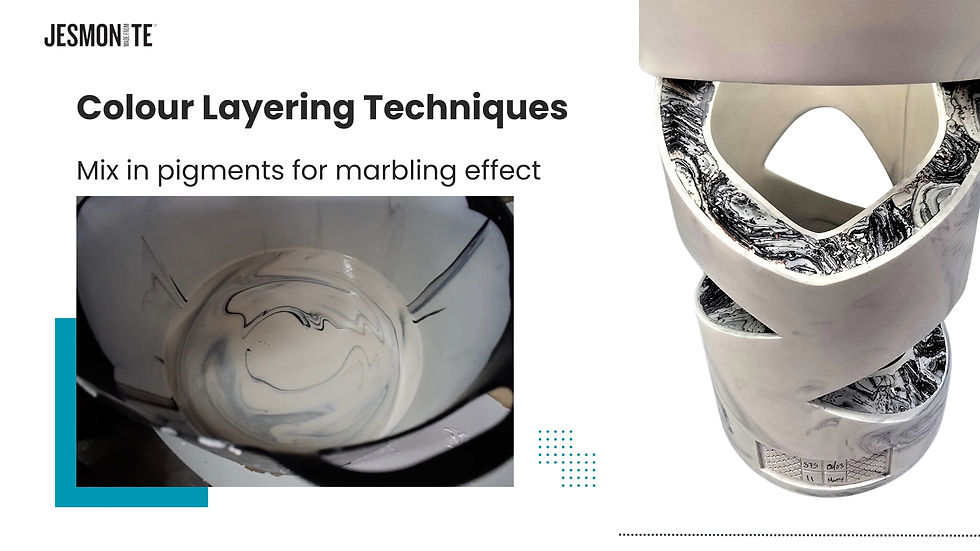

Colour Layering Techniques (Marbling, Veining, Washes)

Unleash Jesmonite's chromatic charisma with layering techniques that infuse panels with life-like depth. For marbling, mix separate batches of Jesmonite with pigments, swirl gently with a stick to create bold, swirling veins without overmixing, then pour into the mould for organic patterns mimicking marble or stone. This yields dramatic contrasts, ideal for ribbed panels where colours dance across ridges.

Veining amps up realism: Drag pigmented Jesmonite through a base layer using a tool, creating fine lines that evoke natural stone cracks, perfect for microcement effects. Washes add subtlety; apply a thin, diluted pigment layer post-demoulding, letting it seep into textures for aged, weathered vibes. Layer multiple washes for gradient depth, as in our terrazzo-style splashbacks. Manufacturers love this for customisation, bespoke colour matching ensures batches align seamlessly, as highlighted in our LinkedIn posts on architectural precision. Experiment boldly; a dash of pigment goes far in crafting irresistible end products.

One of Jesmonite’s standout qualities is its ability to take colour in countless ways:

Pigmenting the base mix for consistent tones.

Layering washes to create depth, patina, or microcement-style variations.

Marbling or veining by blending multiple pigmented mixes together.

Dry brushing or sponging to highlight raised details in ribbed or fluted panels.

With practice, you can achieve anything from sleek minimal finishes to rich stone effects that look centuries old.

Installing Panels: Adhesive or Mechanical Fixing?

When it comes to installation, Jesmonite panels offer flexibility, choose based on scale and setting. Adhesive fixing shines for seamless, lightweight applications: Use high-bond construction adhesives on clean, primed surfaces for quick, invisible joins in homes or hotels, reducing visible hardware and enhancing aesthetics. It's ideal for smaller panels, like decorative features, but ensure substrate compatibility to avoid delamination.

For larger or load-bearing installs, mechanical fixing reigns supreme, drill and secure with screws or brackets, often combined with adhesives for hybrid strength. This method excels in high-traffic hotel areas, providing robust hold against vibrations or weather, as per our engineering guidelines. Consult a structural engineer for overhead or facade work. Manufacturers can embed fixings during casting for foolproof integration, turning panels into easy-to-install masterpieces that wow clients.

Panels can be fixed in two main ways:

Adhesive fixing – suitable for lightweight interior panels, using construction adhesives directly onto plasterboard or masonry.

Mechanical fixing – preferred for larger panels, commercial spaces, or where fire and building regulations require it. Panels can be fixed with hidden clips, screws, or a subframe system.

Jesmonite’s lightweight properties make installation faster and less reliant on heavy equipment.

Top Tips for Achieving Seamless Joins

The crowning touch? Immaculate joins that make panels flow like a single, sculpted surface. Start with precise moulding, ensure edges are straight and sanded smooth post-demoulding to eliminate gaps. Use Jesmonite slurry or filler to bridge any seams, blending textures with a sculpting tool for invisibility.

Align panels meticulously during install; dry-fit first, then apply adhesive evenly to avoid bulges. For colour consistency, match batches and apply washes across joins. Sand lightly and seal with Jesmonite sealer for weatherproof unity. In manufacturing, test joins in prototypes to refine processes. These tips, drawn from our hands-on tutorials, ensure end products like grand feature walls deliver flawless elegance.

When wall panels are installed side by side, neat joins are essential. Here’s how to achieve them:

Chamfer panel edges slightly to avoid sharp visible seams.

Use colour-matched fillers to disguise gaps.

Plan the layout to minimise visible joints – for example, aligning seams with room corners or architectural breaks.

Sand and blend if required, especially with textured or microcement effects.

The result is a clean, continuous surface that looks carved from a single material.

Ready to elevate your manufacturing game with Jesmonite? Explore more inspiring projects on jesmoniteprojects.com/blog or follow us on LinkedIn for the latest innovations. Let's craft textures that transform spaces!

.png)

Comments